|

|

Tube Forming & Machine, Inc. |

Tube Forming Engineering & Design |

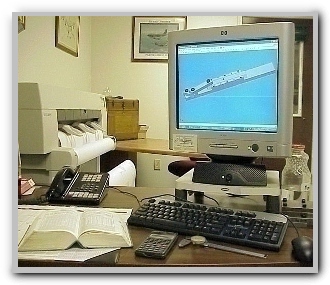

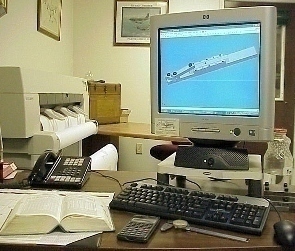

Tube Forming and Machine has an Engineering and Sales department that can assist you in specifying your design requirements, from quote to product delivery, utilizing 2-D tube layouts and 3-D solid modeling, we have the capability of assisting in your design process. Our state of the art CAD software is updated regularly to better serve you. When determining your tube design specifications, it is suggested that you do not use bend radii smaller than 1.5 times the diameter of the tube and if possible avoid placing radii near the tube end points. |

4614 Industrial Row, Oscoda, Michigan 48750 Phone:(989) 739-3323, Fax: (989)739-5403 E-Mail: information@tubeforming.com |

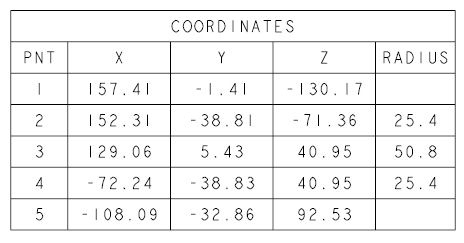

Prints that identify bend radii and the straight centerline intersection points in an XYZ format tend to be the preferred method of specifying tube geometry (see Figure 1). Also, include the tubing outside diameter, wall thickness, material type and any unique features the tube may have. Electronic print file formats that we are able to work with are: * AutoCAD * Autodesk Inventor * TubeCAD * DXF, IGES, STEP * Graphics files (TIFF, JGP, PDF, CGM etc.) |

Figure 1 |